Desulfurization of Zawia Refinery Diesel Using Adsorption Fixed Bed Process

Main Article Content

Abstract

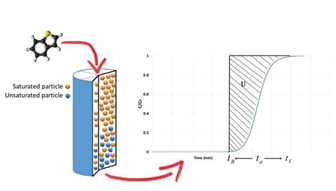

The study focuses on the dynamic modeling of a fixed-bed adsorber for the adsorption of sulfur compounds in diesel fuel. The model considers non-ideal plug flow behavior and velocity variation along the column, providing a more realistic representation of the adsorption process. Additionally, internal mass-transfer resistances due to pore diffusion mechanisms are incorporated into the model. The study investigates adsorption performance by examining different flow rates (5 cc/min, 10 cc/min, 15 cc/min, and 20 cc/min) and inlet concentrations ranging from 586 to 100 ppm. The bed height is constant at 30 cm. The behavior of various parameters, such as bed utilization, breakpoint time, film mass transfer coefficient, and height of the adsorption zone, is analyzed. The results indicate that a sharp front of the breakthrough curve is observed, followed by the broadening of the tail of the breakthrough curve. The breakthrough curve represents the adsorbate concentration in the effluent stream over time. The investigation reveals that a high flow rate of 20 cc/min and a high inlet concentration yield better overall bed capacity utilization for the adsorption system. This means that the bed is more effectively utilized at higher flow rates and higher inlet concentrations, leading to improved adsorption performance. In conclusion, high flow rates and high inlet concentrations are favorable for enhancing the adsorption system's performance in terms of bed utilization. These results provide valuable insights for optimizing the design and operation of fixed-bed adsorbers that remove sulfur compounds from diesel fuel.

Downloads

Article Details

Authors who publish with this journal agree to the following terms:

- Copyright of the published article belongs to the authors and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-ShareAlike 4.0 (CC BY SA) International License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See the Effect of Open Access).

References

O. T. Qazvini and S. Fatemi, “Modeling and simulation pressure-temperature swing adsorption process to remove mercaptan from humid natural gas; A commercial case study,” Sep. Purif. Technol., vol. 139, pp. 88–103, 2015, doi: 10.1016/j.seppur.2014.09.031.

I. Schifter, L. Díaz, M. Vera, E. Guzmán, and E. López-Salinas, “Impact of sulfur-in-gasoline on motor vehicle emissions in the metropolitan area of Mexico City,” Fuel, vol. 82, no. 13, pp. 1605–1612, 2003, doi: 10.1016/S0016-2361(03)00118-2.

S. Gooneh-Farahani and M. Anbia, “A review of advanced methods for ultra-deep desulfurization under mild conditions and the absence of hydrogen,” J. Environ. Chem. Eng., vol. 11, no. 1, p. 108997, 2023, doi: 10.1016/j.jece.2022.108997.

F. L. Plantenga and R. G. Leliveld, “Sulfur in fuels: More stringent sulfur specifications for fuels are driving innovation,” Applied Catalysis A: General, vol. 248, no. 1–2. Elsevier, pp. 1–7, 2003, doi: 10.1016/S0926-860X(03)00133-9.

M. B. Hossain, M. R. Islam, K. M. Muttaqi, D. Sutanto, and A. P. Agalgaonkar, “Advancement of fuel cells and electrolyzers technologies and their applications to renewable-rich power grids,” J. Energy Storage, vol. 62, p. 106842, 2023, doi: 10.1016/j.est.2023.106842.

N. H. Behling, Fuel Cells: Current Technology Challenges and Future Research Needs. Newnes, 2012.

M. Singh, D. Zappa, and E. Comini, “Solid oxide fuel cell: Decade of progress, future perspectives and challenges,” Int. J. Hydrogen Energy, vol. 46, no. 54, pp. 27643–27674, 2021, doi: 10.1016/j.ijhydene.2021.06.020.

A. Haruna, Z. Merican Aljunid Merican, S. Gani Musa, and S. Abubakar, “Sulfur removal technologies from fuel oil for safe and sustainable environment,” Fuel, vol. 329, p. 125370, 2022, doi: 10.1016/j.fuel.2022.125370.

K. H. Choi, Y. Korai, I. Mochida, J. W. Ryu, and W. Min, “Impact of removal extent of nitrogen species in gas oil on its HDS performance: An efficient approach to its ultra deep desulfurization,” Appl. Catal. B Environ., vol. 50, no. 1, pp. 9–16, 2004, doi: 10.1016/j.apcatb.2003.10.011.

M. Ren, F. Fan, B. Zhou, X. Liang, and Z. Yang, “Dynamic simulation of adsorption desulfurization from diesel fuel over activated carbon in the fixed bed,” Chem. Eng. Res. Des., vol. 183, pp. 274–284, 2022, doi: 10.1016/j.cherd.2022.04.029.

Z. Lu et al., “Effect of granular activated carbon pore-size distribution on biological activated carbon filter performance,” Water Res., vol. 177, p. 115768, 2020, doi: 10.1016/j.watres.2020.115768.

M. Gayathiri, T. Pulingam, K. T. Lee, and K. Sudesh, “Activated carbon from biomass waste precursors: Factors affecting production and adsorption mechanism,” Chemosphere, vol. 294, p. 133764, 2022, doi: 10.1016/j.chemosphere.2022.133764.

T. M. Peacok et al., “Mathematical tool based on breakthrough curves to evaluate the economic advantages of chemical regeneration of activated carbon in power plants: A comparative study,” Appl. Sci., vol. 11, no. 24, p. 11786, 2021, doi: 10.3390/app112411786.

C. A. V. Burkert, G. N. O. Barbosa, M. A. Mazutti, and F. Maugeri, “Mathematical modeling and experimental breakthrough curves of cephalosporin C adsorption in a fixed-bed column,” Process Biochem., vol. 46, no. 6, pp. 1270–1277, 2011, doi: 10.1016/j.procbio.2011.02.016.

A. Poursaeidesfahani et al., “Prediction of adsorption isotherms from breakthrough curves,” Microporous Mesoporous Mater., vol. 277, pp. 237–244, 2019, doi: 10.1016/j.micromeso.2018.10.037.

S. Moradi, E. Moosavi, and R. Karimzadeh, “Stability determination of the modified activated carbon to adsorb thiophenic compounds from model diesel fuel,” Iran. J. Chem. Chem. Eng., vol. 38, no. 4, pp. 149–165, 2019.

R. N. Fallah and S. Azizian, “Removal of thiophenic compounds from liquid fuel by different modified activated carbon cloths,” Fuel Process. Technol., vol. 93, no. 1, pp. 45–52, 2012, doi: 10.1016/j.fuproc.2011.09.012.

P. Wang and Rizwan-uddin, “A modified, hybrid nodal-integral/finite-element method for 3D convection-diffusion problems in arbitrary geometries,” Int. J. Heat Mass Transf., vol. 122, pp. 99–116, 2018, doi: 10.1016/j.ijheatmasstransfer.2018.01.087.

I. Jarrah and Rizwan-uddin, “Nodal integral methods in general 2D curvilinear coordinates - applied to convection–diffusion equation in domains discretized using quadrilateral elements,” Int. J. Heat Mass Transf., vol. 187, p. 122559, 2022, doi: 10.1016/j.ijheatmasstransfer.2022.122559.

L. H. Macfarlan, M. T. Phan, and R. B. Eldridge, “Methodologies for Predicting the Mass Transfer Performance of Structured Packings with Computational Fluid Dynamics: A Review,” Chem. Eng. Process. - Process Intensif., vol. 172, p. 108798, 2022, doi: 10.1016/j.cep.2022.108798.

U. K. Traegner and M. T. Suidan, “Evaluation of surface and film diffusion coefficients for carbon adsorption,” Water Res., vol. 23, no. 3, pp. 267–273, 1989, doi: 10.1016/0043-1354(89)90091-2.

Y. Seida, N. Sonetaka, K. E. Noll, and E. Furuya, “Determination of Pore and Surface Diffusivities from Single Decay Curve in CSBR Based on Parallel Diffusion Model,” Water (Switzerland), vol. 14, no. 22, p. 3629, 2022, doi: 10.3390/w14223629.

E. Furuya, Y. Takeuchi, and K. E. Noll, “Intraparticle diffusion of phenols within bidispersed macroreticular resin particles,” J. Chem. Eng. Japan, vol. 22, no. 6, pp. 670–676, 1989, doi: 10.1252/jcej.22.670.

B. Chen, C. W. Hui, and G. Mckay, “Film-pore diffusion modeling for the sorption of metal ions from aqueous effluents onto peat,” Water Res., vol. 35, no. 14, pp. 3345–3356, 2001, doi: 10.1016/S0043-1354(01)00049-5.

B. V. Babu and C. A.S., “Pyrolysis of Shrinking Cylindrical Biomass Pellet,” in Proceedings of International Symposium and 56th Annual Session of IIChE, 2003, vol. 333031, no. 14, pp. 19–22.

B. Babu and A. Chaurasia, “Modeling & simulation of pyrolysis: influence of particle size and temperature,” in … of International conference on multimedia and …, 2002, vol. 333031, pp. 103–128, [Online]. Available: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.5.7354&rep=rep1&type=pdf.

B. V. Babu and A. S. Chaurasia, “Modeling, simulation and estimation of optimum parameters in pyrolysis of biomass,” Energy Convers. Manag., vol. 44, no. 13, pp. 2135–2158, 2003, doi: 10.1016/S0196-8904(02)00237-6.

B. V Babu and A. S. Chaurasia, “Modeling, simulation of pyrolysis: effect of convective heat transfer & orders of reactions,” in International Symposium and 55th Annual Session of IIChE. CHEMCON, 2002, pp. 105–106, [Online]. Available: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.207.1683&rep=rep1&type=pdf.

B. V. Babu and A. S. Chaurasia, “Heat transfer and kinetics in the pyrolysis of shrinking biomass particle,” Chem. Eng. Sci., vol. 59, no. 10, pp. 1999–2012, 2004, doi: 10.1016/j.ces.2004.01.050.

B. V. Babu and A. S. Chaurasia, “Pyrolysis of biomass: Improved models for simultaneous kinetics and transport of heat, mass and momentum,” Energy Convers. Manag., vol. 45, no. 9–10, pp. 1297–1327, 2004, doi: 10.1016/j.enconman.2003.09.013.

B. V. Babu and A. S. Chaurasia, “Parametric study of thermal and thermodynamic properties on pyrolysis of biomass in thermally thick regime,” Energy Convers. Manag., vol. 45, no. 1, pp. 53–72, 2004, doi: 10.1016/S0196-8904(03)00130-4.

A. S. Chaurasia, A. S. Chaurasia, and B. V Babu, “Modeling Simulation Of Pyrolysis Of Biomass: Effect Of Thermal Conductivity, Reactor Temperature And Particle Size On Product Concentrations,” in Galgotias University, 2003, pp. 1–7.

B. V Babu and A. S. Chaurasia, “Optimization of Pyrolysis of Biomass Using Differential Evolution Approach,” in In Proceedings of the second international conference on computational intelligence, robotics, and autonomous systems (CIRAS-2003), Singapore, 2003, pp. 15–18.

M. H. Armbruster and J. B. Austin, “The Adsorption of Gases on Plane Surfaces of Mica,” J. Am. Chem. Soc., vol. 60, no. 2, pp. 467–475, 1938, doi: 10.1021/ja01269a066.

The Editors of Encyclopaedia, “Van Der Waals Forces,” Britannica, 2024. www.britannica.com/science/van-der-Waals-forces (accessed Jan. 13, 2024).

M. Natarajan, S. Mohan, B. R. Martinez, M. L. Meltz, and T. S. Herman, “Antioxidant compounds interfere with the 3-[4,5-dimethylthiazol-2-yl]-2, 5-diphenyltetrazolium bromide cytotoxicity assay,” Cancer Detect. Prev., vol. 24, no. 5, pp. 405–414, 2000.

Z. Nemes, R. Dietz, J. B. Lüth, S. Gomba, E. Hackenthal, and F. Gross, “The pharmacological relevance of vital staining with neutral red,” Experientia, vol. 35, no. 11, pp. 1475–1476, 1979, doi: 10.1007/BF01962793.

K. Nikolic and D. Agababa, “Design and QSAR study of analogs of γ-tocotrienol with enhanced antiproliferative activity against human breast cancer cells,” J. Mol. Graph. Model., vol. 27, no. 7, pp. 777–783, 2009, doi: 10.1016/j.jmgm.2008.11.007.

H. K. Abdullabass, A. M. Jawad, and N. M. Aljamali, “Synthesis of Drug Derivatives As Inhibitors of Cancerous Cells,” Biochem. Cell. Arch., vol. 20, no. 2, pp. 5315–5322, 2020.

N. M. Aljamali and I. O. Alfatlawi, “Synthesis of sulfur heterocyclic compounds and study of expected biological activity,” Res. J. Pharm. Technol., vol. 8, no. 9, pp. 1225–1242, 2015, doi: 10.5958/0974-360X.2015.00224.3.

N. M. Aljamali and I. K. A. Alsabri, “Development of trimethoprim drug and innovation of sulfazane-trimethoprim derivatives as anticancer agents,” Biomed. Pharmacol. J., vol. 13, no. 2, pp. 613–625, 2020, doi: 10.13005/bpj/1925.

S. Farber, R. Toch, E. M. Sears, and D. Pinkel, “Advances in Chemotherapy of Cancer in Man,” in Advances in Cancer Research, vol. 4, no. C, Elsevier, 1956, pp. 1–71.

L. F. Bautista, M. Martínez, and J. Aracil, “Adsorption of α-amylase in a fixed bed: Operating efficiency and kinetic modeling,” AIChE J., vol. 49, no. 10, pp. 2631–2641, 2003, doi: 10.1002/aic.690491016.

L. Fernando Bautista, M. Martínez, and J. Aracil, “Modeling of the adsorption of α-amylase in batch stirred tank,” Ind. Eng. Chem. Res., vol. 39, no. 11, pp. 4320–4325, 2000, doi: 10.1021/ie000262+.

L. F. Bautista, M. Martínez, and J. Aracil, “Adsorption equilibrium of α-amylase in aqueous solutions,” AIChE J., vol. 45, no. 4, pp. 761–768, 1999, doi: 10.1002/aic.690450411.

H. Ghasemzadeh, S. Babaei, S. Tesson, J. Azamat, and M. Ostadhassan, “From excess to absolute adsorption isotherm: The effect of the adsorbed density,” Chem. Eng. J., vol. 425, p. 131495, 2021, doi: 10.1016/j.cej.2021.131495.

J. Adolphs and M. J. Setzer, “Description of gas adsorption isotherms on porous and dispersed systems with the excess surface work model,” J. Colloid Interface Sci., vol. 207, no. 2, pp. 349–354, 1998, doi: 10.1006/jcis.1998.5786.

R. Pini, “Interpretation of net and excess adsorption isotherms in microporous adsorbents,” Microporous Mesoporous Mater., vol. 187, pp. 40–52, 2014, doi: 10.1016/j.micromeso.2013.12.005.

A. Ghorbani, R. Karimzadeh, and M. Mofarahi, “Mathematical Modeling of Fixed Bed Adsorption: ϐ Breakthrough Curve,” Dep. Chem. Eng. Tarbiat Modares Univ. Tehran, Iran, pp. 135–143, 2018.

P. J. Lu, C. S. Chang, and J. M. Chern, “Binary adsorption breakthrough curves in fixed bed: Experiment and prediction,” J. Taiwan Inst. Chem. Eng., vol. 45, no. 4, pp. 1608–1617, 2014, doi: 10.1016/j.jtice.2013.10.018.

K. H. Chen, Y. R. Lai, and N. T. D. Hanh, “Breakthrough curve modeling for lysozyme by ion-exchange nanofiber membrane: Linear and nonlinear analysis,” J. Taiwan Inst. Chem. Eng., vol. 13, no. 9, p. 761, 2023, doi: 10.1016/j.jtice.2023.105198.

K.-H. Chen, Y.-R. Lai, N. T. D. Hanh, S. S.-S. Wang, and Y.-K. Chang, “Breakthrough curve modeling and analysis for lysozyme adsorption by tris (hydroxymethyl) aminomethane affinity nanofiber membrane,” Membranes (Basel)., vol. 13, no. 9, p. 761, 2023, doi: 10.3390/membranes13090761.

R. Brion-Roby, J. Gagnon, J. S. Deschênes, and B. Chabot, “Investigation of fixed bed adsorption column operation parameters using a chitosan material for treatment of arsenate contaminated water,” J. Environ. Chem. Eng., vol. 6, no. 1, pp. 505–511, 2018, doi: 10.1016/j.jece.2017.12.032.

I. Ali, “Water treatment by adsorption columns: Evaluation at ground level,” Sep. Purif. Rev., vol. 43, no. 3, pp. 175–205, 2014, doi: 10.1080/15422119.2012.748671.